We see the brilliance of every piece of jewelry, the perfect interpretation of various styles, the fashion and classics of countless brands. But behind this, every piece of jewelry has to go through many processes, such as design, production, polishing, polishing, etc. After countless fine operations, the jewelry presents its gorgeous side. Today, let's take a look at the steps required to make a piece of jewelry.

Step 1: Design drawings

Designers will first draw sketches of new works on paper, and use pencils and gouache to complete the design drawings. This process can range from a few days and a half to a few months. The design details are often revised repeatedly. During the design process, it is necessary to comprehensively consider various factors such as aesthetics, implication, and machinability.

The second step: hand-carved wax

The craftsman engraves the wax plate by hand with reference to the design drawings, which is the most demanding process in the jewelry making process. (This process depends on the complexity, ranging from a day or two to a few days).

Step 3: Wax injection moulding

Custom usually uses lost wax casting to make wax molds into 18K rings. If it is mass production, then the front wax plate will be made into a silver plate and pressed into a film, and the wax mold will be mass produced.

Step 4: Modeling

The moulding is all carried out by hand, and a special calender is used to push back and forth on the surface of the jewelry, which requires the exquisite skills and techniques of the craftsmen, which are accumulated over the years.

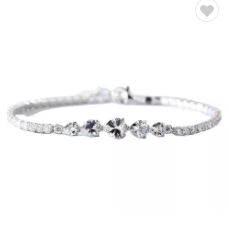

Step 5: Match the Stones

According to the jewelry design drawing, the diamonds or gemstones are sorted by hand, and the suitable color, cut and size are selected, and they are ready to be set.

Step 6: Setting the Gemstones

Setting is a critical part of jewelry making, requiring hand-setting of every diamond and gemstone. If the design is simple, the inlay is relatively easy. If the design involves complex craftsmanship, or uses a large number of gems and diamonds inlaid jewelry, the difficulty will increase exponentially.

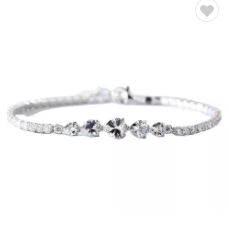

Step 7: Polishing Electro-Gold

After the inlay is completed, the metal surface and details need to be polished, and some jewelry needs to be electro-gold on the surface to make the surface more shiny and bright!

Step 8: Quality Inspection

The finished jewelry is inspected, and if it is unqualified, it needs to be returned to the previous process and then reworked.

The above only shows some important links in the jewelry production process, and there are still many processes that cannot be displayed one by one. A perfect piece of jewelry is revealed in front of us after the hands of countless pairs of craftsmen!