Focus on brand jewelry customization for 20 years, professional brass/stainless steel OEM/ODM jewelry manufacturer

With over 7 million hours dedicated to excellence since 2005, we are the trusted partner for custom manufacturing of premium brass and stainless steel jewelry. For two decades, we have empowered global brands with masterful craftsmanship and unwavering dedication.

Providing jewelry manufacturing services to global fashion jewelry brands

A leader in the brass and stainless steel jewelry manufacturing industry

Global Leader in Custom Fashion Jewelry Manufacturing

Specialized in providing brand owners with efficient jewelry OEM customization services for 20 years

Star Harvest Jewelry boasts a rigorous R&D and quality management system, holding 7 independently developed electroplating patents. Our electroplating coating technology is 2-3 times more advanced than that of our competitors. Furthermore, we have a quality laboratory and 9 quality control checks, achieving a production pass rate exceeding 97%.

With a transparent production system and advanced management standards 30% higher than the industry average, we guarantee a 97% on-time delivery rate.

Our clients benefit from real-time production tracking, ensuring consistent supply and zero unexpected delays.

Leveraging our deep industry resources and self-owned factory, we achieve 15–20% lower production costs than industry averages. This direct advantage allows us to pass on significant savings to you, ensuring uncompromised quality while empowering your brand’s price competitiveness in the marke.

Our COO and Vice President each bring over 30 years of directly relevant industry experience.

The backbone of our team boasts an impressive average of 15+ years of dedicated service within our company.

Leverage this collective experience and stability for reliable production timelines, uncompromising quality control, and meticulous attention to detail in every piece we craft.

Every client is supported by an exclusive engineering, production, and QC team who understand their product needs in depth.

We conduct:

Each OEM project is guided by a cross-functional unit – your personal liaison merging engineering expertise, production mastery, and QC precision. This team becomes an extension of your brand, mastering every design nuance to deliver on your exact specifications

We institutionalize client success through:

Achieve the brand dream, create the future together

Since 2005, Star Harvest, a leading custom jewelry jewelry supplier, has been focusing on the custom manufacturing of high-quality brass and stainless steel jewelry, committed to providing one-stop jewelry customization services from R&D, design, production to packaging for global brands. In the field of OEM/ODM customization, our jewelry factory has more than 20 years of rich industry experience and is a trusted custom jewelry supplier, dedicated to supporting customers in realizing brand value and achieving sustainable growth.

We provide one-stop OEM customization services, covering the entire process of custom jewelry manufacturing. Whether it is pre-design data research or the realization of design effects to mass production and promotional material shooting, Star Harvest, a professional custom jewelry manufacturer, truly realizes full-link service support from concept to market.

Relying on the sh database, we provide analysis of styles, trends, marketing concepts, etc., helping you analyze product audiences to quickly adapt to the market

Our top design team can restore the design draft 1:1, provide design documents, and propose process and production improvement suggestions to help you achieve the best product, stable mass production, and avoid production cost waste.

From design to sample production, we can complete proofing within 7 days at the fastest, helping you optimize your product structure. Each product comes with a feasibility report for mass production.

We can produce and deliver 300,000-500,000 products every month

We partner with customers to develop precise quality blueprints. Our engineering team then defines specific process parameters for each SKU, ensuring optimal quality, cost, and consistent production.

StarHarvest is equipped with a dedicated laboratory and R&D team to develop specific materials, electroplating colors, texture processes or specific product designs according to your needs.

Integrate your brand into the packaging, provide FSC certified packaging and personalized packaging customization, including packaging requirements of different styles, materials and sizes

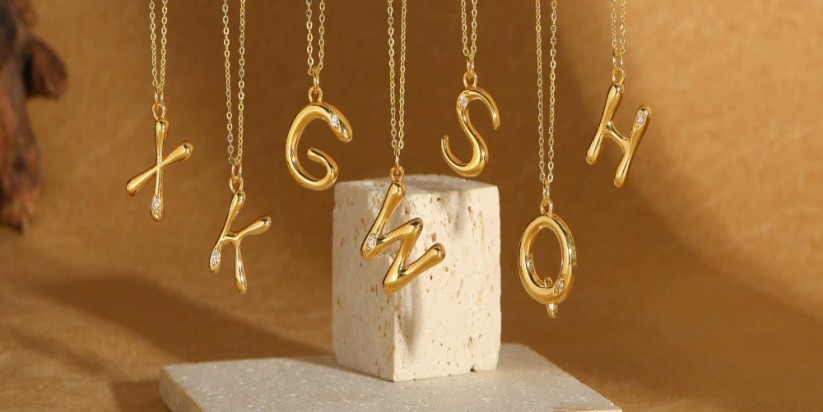

Our professional photography team can provide product white background images/scenery images, and can output promotional materials that are suitable for e-commerce platforms/social media/websites, saving you time in promotion and distribution.

A leading global manufacturer of bespoke jewelry, creating exclusive pieces for jewelry brands worldwide.

We focus on providing professional and efficient OEM/ODM solutions for jewelry brand development, leveraging our expertise in brass and stainless steel. We do not engage in wholesale, retail, or any direct sales business.

We specialize in OEM/ODM production of brass and stainless steel jewelry . Our services offer full customization of material hardness, thickness, and surface finishes, including polished, brushed, antique, and PVD rose gold plating. We provide fast sample production (within 3-7 days) to verify design feasibility and also support eco-friendly coatings and hypoallergenic materials to ensure global market compliance.

Backed by over 20 years of expertise in jewelry customization, our factory crafts bespoke brass and stainless steel designs tailored to your unique vision. We dedicate ourselves to delivering unmatched style options and unwavering quality, ensuring your concepts translate flawlessly from sketch to final creation. Focus purely on your design innovation—we handle the entire process, guaranteeing consistent beauty and reliability.

Star Harvest offers virtually every type of gemstone available on the market, from ethically sourced natural gems to premium lab-grown gems, all with internationally recognized certifications to help you achieve your design goals. Our exquisite craftsmanship transforms gemstones into unique designs, providing precise, custom cuts and sophisticated micro-setting techniques. Each project undergoes rigorous quality control to ensure seamless customization and minimize uncertainties during production.

We provide comprehensive jewelry plating processes, with technology 2-3 times more advanced than that of our competitors. This includes PVD plating on stainless steel, delivering vibrant monochrome, multi-color, and gradient finishes. Each coating achieves 99.8% color fidelity, meets global jewelry safety standards, and ensures durable quality that significantly exceeds benchmark abrasion resistance.

We specialize in bulk custom design and production of high-quality jewelry accessories, including chains, clasps, and link rings. Backed by years of precision manufacturing experience, we guarantee lead-free components and full compliance with industry safety standards. Our premium equipment delivers accessories with tight tolerances down to 0.1mm for seamless performance.

With a library of 20,000+ brass and stainless steel styles, we offer light customization options, including logo stamping, size adjustments, accessory replacements, and pattern customizations. All products meet environmental certifications, are accompanied by quality inspection reports, and comply with ISO 9001 standards and Amazon FBA packaging requirements, enabling fast distribution with minimal development costs.

Jewelry quality control is a systematic process that spans from raw materials to finished product testing. We ensure that each piece of jewelry meets rigorous standards for consistency, durability, safety, and aesthetic appeal.

We conduct rigorous inspections on all copper and stainless steel raw materials before production. Each batch is verified for material integrity, surface quality, and safety compliance — ensuring non-toxic, durable components ready for global markets. This end-to-end source control guarantees consistent quality and regulatory peace of mind.

During wax prototyping, we meticulously cross-verify models against original designs. This process safeguards dimensional consistency, structural soundness, and aesthetic proportions — catching discrepancies before casting to prevent expensive mold re-engineering.

Every metal casting undergoes rigorous quality screening post-production. We examine surfaces for imperfections and verify structural integrity, ensuring flawless components ready for finishing — no porous defects, distortions, or hidden flaws reach the next stage.

Welding integrity is assured through layered verification. Both craft precision and technological scrutiny guarantee secure joints, seamless contours, and immaculate surfaces — systematically eliminating imperfections that compromise durability.

Pre-plating safeguards eliminate variables that compromise finish quality. We ensure pristine base surfaces, optimized bonding layers, and true-to-spec color deposition — establishing the foundation for enduring luster and adhesion.

Post-plating validation guarantees enduring beauty. Every finish undergoes real-world resistance verification, maintains uniform luster across textures, and delivers contact-ready surfaces that withstand daily wear while retaining pristine aesthetics.

We implement strict quality control on each batch of jewelry to ensure its sturdiness and beauty: this includes repeatedly testing the smoothness of the clasp opening and closing, verifying the security of the gemstone setting, carefully inspecting the appearance for scratches or discoloration, and strictly sampling and inspecting each batch according to standards and recording reports.

Before leaving the factory, we conduct three final rigorous checks:

At the core of our business is a customer-centric approach. We take the time to understand your unique needs and collaborate closely with you to deliver customized jewelry solutions that perfectly align with your brand. As more than just a supplier, we are a trusted partner, committed to driving value and success for your jewelry business.

“We have been working with StarHarvest for over 3 years and their quality control is impeccable. In our recent order of 50,000 pieces, their stainless steel chain had a defect rate of less than 0.5%. What impressed us most was that they proactively provided a report on the plating thickness before shipping – exactly the kind of diligence we need.”

“As a fast-growing DTC brand, we value their 45-day standard turnaround on custom designs. They produced our geometric brass collection with perfect symmetry – all 120 angles were within 0.1mm tolerance. Their production updates every 48 hours gave us total visibility.”

“Their material certification system is thorough. Each brass alloy batch comes with mill test reports showing exact composition. When we requested lead-free compliance documentation for EU market, they provided full test reports within 12 hours. This level of professionalism is rare.”

“Star Harvest’S Responsiveness Saved Us A Major Holiday Production. When We Needed A Last-Minute Modification To A Stainless Steel Pendant, Their Engineering Team Had Cad Adjustments Ready Within 6 Hours. Their Sample Accuracy Means We Can Now Skip Prototyping—The First Batch Is 95% Production-Ready.”

“Their Brass Finishing Consistently Meets Our High Standards. We’Ve Ordered 7 Different Antique Finishes Over 18 Months – Every Batch Matches The Approved Master Sample Exactly. Oxidation Resistance Testing Showed 30% Better Performance Than Our Previous Vietnam Supplier.”

“Their Defect Replacement Policy Is Outstanding. When 2% Of A Brass Ring Shipment Showed Casting Flaws (Our Qc Found It), They Air Shipped Replacements In 3 Days Without Paperwork Delays. We’Ve Reduced Inspection Costs By 40% Since Switching To Them.”

We specialize in turning your jewelry ideas into high-quality, market-ready products. Whether you need 100 samples quickly or 200,000 units for a major launch, our vertically integrated factory manages every step—from 3D prototyping (with a 12-48 hour turnaround) to custom plating in recycled or lead-free materials. Trusted by over 300 brands over these years, we’re dedicated to bringing your designs to life, no matter the scale.